As global sourcing strategies shift in a post-pandemic world, Vietnam has emerged as a competitive hub for furniture manufacturing. Once known mainly for its low labor costs, the country is now recognized for a broader set of advantages, from modern production capabilities to favorable trade agreements, making it an increasingly strategic choice for B2B buyers.

However, finding the right manufacturer requires more than browsing online directories or requesting price quotations. A successful sourcing decision hinges on understanding production capabilities, quality systems, export experience, and how flexible a supplier can be when it comes to minimum order quantities (MOQs).

Vietnam’s Advantage: A Mature, Cost-Effective Ecosystem

Vietnam’s furniture industry has evolved rapidly. Labor costs remain competitive, with average factory wages ranging between $250 and $450 per month, but that is no longer the only reason international buyers turn to this market.

Across major manufacturing clusters such as Binh Duong, Dong Nai, and the central provinces like Hue, factories are investing in advanced machinery: CNC wood routers, robotic sanding arms, automated kilns, and polyurethane foam injection systems. These improvements allow Vietnamese manufacturers to increase production capacity without compromising on consistency or quality, a key concern for brands managing retail and private label programs.

At the same time, free trade agreements such as the EVFTA and CPTPP are giving Vietnamese exports preferential access to key markets in Europe and the Pacific, further boosting the cost-effectiveness of sourcing from the country.

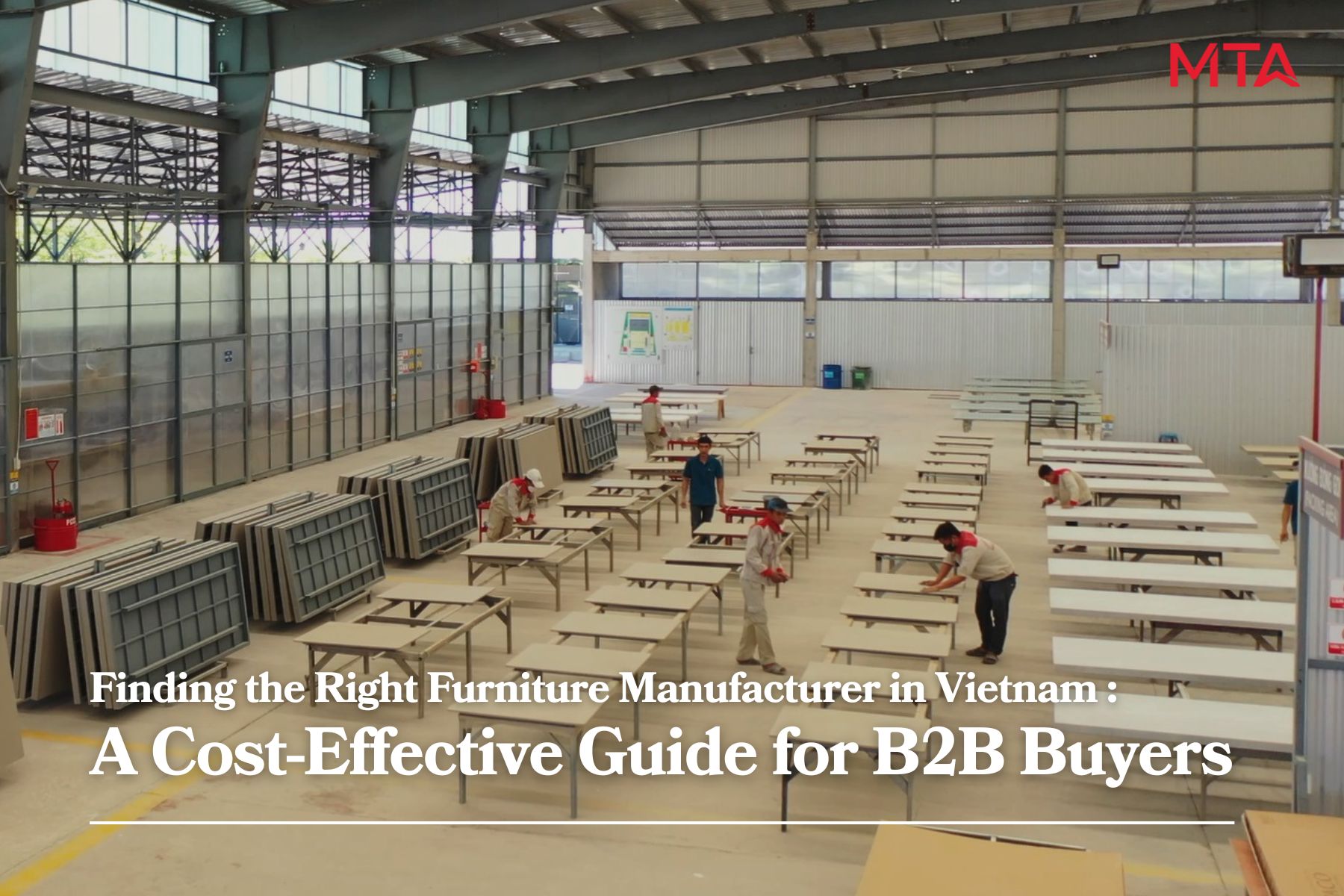

In this video, we take you on a factory tour of a Vietnamese furniture manufacturer known for producing affordable, export-ready furniture. You’ll see the full process — from raw material preparation to final packaging — and understand how buyers around the world are sourcing low-cost yet quality furniture from Vietnam.

Beyond Price: Matching Buyer Needs with Manufacturer Capabilities

For B2B buyers, cost is important, but not in isolation. A low quote is only meaningful if the manufacturer can deliver consistent quality, meet deadlines, and scale production when needed.

Manufacturers in Vietnam vary widely in size and specialization. Some are family-owned businesses focused on artisanal woodwork, while others operate at scale as full-service OEM or ODM partners. The ideal supplier will depend on your sourcing objectives — whether that’s agility for fast product launches, reliable volume for recurring orders, or support for design and customization.

A critical factor is vertical integration. Manufacturers that control their own material sourcing, component processing, and final assembly tend to offer better lead times and more predictable outcomes. This is especially relevant for buyers dealing with mixed-material furniture, where wood, metal, ceramic, or upholstery must come together under one production flow.

MOQ Flexibility and Sampling Agility

Unlike some larger factories in other regions, many Vietnamese manufacturers are open to low or medium MOQs, particularly when the buyer can commit to container-based loading strategies. This flexibility is a significant advantage for companies testing new product lines or managing seasonal collections.

Sampling speed is another indicator of supplier professionalism. A responsive factory that can develop prototypes quickly and adjust based on feedback often signals better communication and tighter control over production planning.

Quality Control Is No Longer Optional

As the global market demands higher compliance standards, Vietnamese manufacturers have stepped up. Many now hold certifications such as ISO 9001, FSC for sustainable wood sourcing, and BSCI for ethical production practices.

More importantly, top-tier factories are integrating quality control directly into their production workflows. Moisture content testing, in-line inspections, drop tests, and barcoded tracking systems are becoming more common. These measures not only reduce the risk of product failure but also improve traceability, a growing priority for buyers in regulated markets.

Visiting a factory in person remains the best way to verify these systems, but high-quality video tours or third-party audits can offer valuable insights when travel is not possible.

The Role of Local Knowledge in Supplier Selection

The most capable manufacturers are not always the most visible online. Many excellent factories in Vietnam do not maintain an active digital presence or attend overseas trade fairs. This makes on-the-ground research and local expertise essential.

Industry trade shows such as VIFA Expo, HawaExpo, or regional events in Binh Duong and Ho Chi Minh City provide valuable face-to-face interaction. However, for buyers without local teams, working with a sourcing partner or consultant can bridge the gap. These professionals can vet suppliers, manage negotiations, monitor production timelines, and handle quality control on-site — helping buyers avoid costly missteps.

A Long-Term View on Cost-Effective Sourcing

Vietnam is no longer just a low-cost alternative to China. It is becoming a preferred destination for companies seeking a balance between price, quality, flexibility, and long-term supplier relationships.

For B2B buyers, the goal is not to find the cheapest manufacturer, but the most suitable one, a partner who understands your brand’s expectations, offers scalable capacity, and delivers consistent value throughout the supply chain.

By applying a thoughtful, strategic approach to factory selection, companies can unlock both short-term savings and long-term reliability. Vietnam’s dynamic and maturing furniture industry offers the tools — and the talent — to meet the evolving demands of today’s global furniture market.